Research

- English

- Türkçe

We work on various thermoplastic processing methods for fabrication of miniature devices with features of typical characteristic dimensions of less than 1 mm. We are particularly experienced in fabrication of microfluidic lab-on-a-chip devices and components. Therefore, we also work on design and characterization of microfluidic components such as micromixers, micropumps, microvalves, and various microfluidic devices for life sciences.

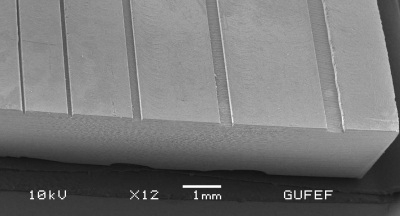

Hot Embossing

Hot embosing is the process of replicating negatives of features on a substrate by simultaneously applying heat and pressure. Particularly in hot embossing of miniature thermoplastic devices, the mold with the micro-scale protrusions fabricated by micromilling or lithography based techniques, is compressed on a thermoplastic substrate at a temperature greater than the substrate material's glass transition temperature.

Microchannels embossed on polymethylmethacrylate (PMMA) substrate.

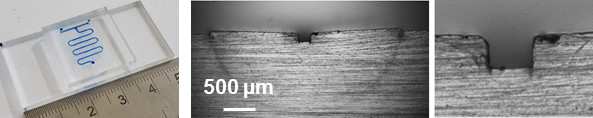

Ultrasonic Embossing

It is possible to emboss features on a thermoplastic substrate by assisting the embossing process by ultrasonic (~30 kHz) vibrations. In this process, need for additional heating is eliminated and pressure needed for embossing is greatly reduced. The cycle time can be as low as a few seconds.

Ultrasonically embossed and sealed serpentine micromixer. Typical cross-section of ultrasonically embossed microchannel. The semi circular ring around the channel is the boundary of process-affected zone in ultrasonic embossing. The close-up view of the cross-section.1

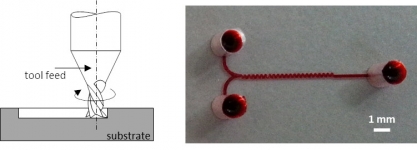

Micromilling

Micromilling is basically the same as the conventional milling operation, but the tools are typically end-mills with diameters less than 1 mm. The process is mostly carried out at high spindle speeds (upto about 100,000 rpm).

Illustration of micromilling operation. A micromixer fabricated by micromilling.2

1 F. Çoğun, M.A.S. Arıkan, E. Yıldırım, "Investigation of process-affected zone in ultrasonic embossing of microchannels on thermoplastic substrates", Journal of Manufacturing Processes, vol. 50, 394-402, 2020. https://doi.org/10.1016/j.jmapro.2019.12.055

2 Yıldırım, E. (2017). Analysis and testing of a contraction-and-expansion micromixer for micromilled microfluidics. Microsystem Technologies, 23(10), 4797–4804. https://doi.org/10.1007/s00542-017-3291-2