Projects

- English

- Türkçe

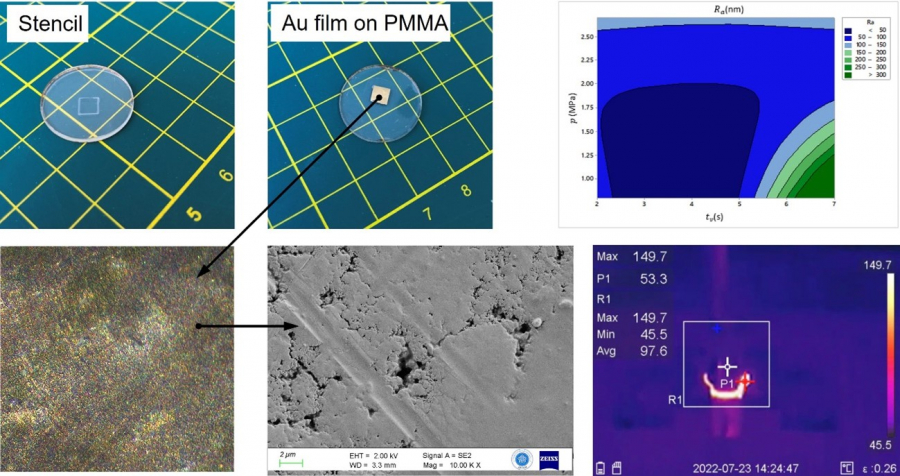

An Ultrasonic-assisted Method for Fabrication of Metal Layers with Controlled Surface Quality for Thermoplastic Lab-on-a-chip Systems**Funded by the Scientific and Technological Research Council of Türkiye (TÜBİTAK) with grant no. 121M427 In this project, we aim to develop a scalable process for making metal layers with a controlled surface roughness on thermoplastic substrates for lab-on-a-chip applications. Firstly, a stencil defining the metal layer is cut by xurography on a protective film covering the substrate. Then, the substrate is treated with the solvent of the thermoplastic substrate for a specific time. In the following step, metal nanopowder is laid on the stencil. Next, the powder is pressed on the substrate via an ultrasonic horn vibrating at a frequency of around 30 kHz. The vibration causes rapid heating of the substrate locally and sintering of the nanopowders. Solvent treatment ensures the embedding of the powders onto the substrate. After the vibration is ceased, the substrate is cooled down while being compressed by the sonotrode. After cooling, the stencil is removed revealing the metal layer on the substrate. The process parameters, namely the pressure applied by the sonotrode on the substrate and the vibration time, affect the surface roughness of the metal layer. The figure below shows the stencil on the polymethyl methacrylate substrate and the resulting gold layer. Close-up and SEM image of the gold layer reveals the sintering effect with some voids remaining as defects. The thermal camera image proves the heating effect caused by ultrasonic vibration. Our group is currently working on the improvement of the process to eliminate any defects on the metal layer. Patent pending TR2022/019904. |

| Project team:

PI: Assoc. Prof. Ender Yıldırım (METU ME), Researchers: Prof. M.A. Sahir Arıkan (METU ME), Prof. Uğur Tamer (Gazi Uni., Faculty of Pharmacy, Analytical Chemistry) Students: Ayşen Gümüştaş (former), Erdem Bayraktar, Mert Kerem Ülkü, Mert Nakışlı, Miray Sanem Sarı, Sarah Farahani (former) |